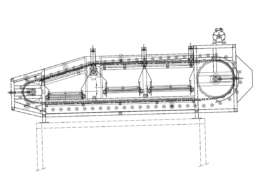

C500 Sizer

Initial selection = Yield and more quality.

By inserting the sizer in line, it is possible to eliminate sagging and inconsistent tomatoes, as well as select and divide the tomato according to its size.

The main feature is that of having an adjustment range that goes from 20 to 75 mm; in this way, the Manufacturer can choose the size of the tomato that best suits the peeled and diced tomato line, and the one that best suits the concentrate product line.

It consists of conveyor rollers, which during their motion allow you to size the tomato; the 1st caliber generally separates the tomato waste and fragments, while the 2nd caliber allows small tomatoes being conveyed to the same shredding group.

The 3rd caliber allows you to select large tomatoes and convey them, through a special conveyor belt, to the optical sorter and then to the peeling and dicing line.

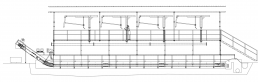

Porter elevator

It is used for transporting the product at height.

- Sturdy structure in tubular section of AISI 304 stainless steel.

- Support frame in tubular section of AISI 304 stainless steel with adjustable feet.

- Mesh belt in FDA certified food-grade polypropylene composed of reinforced and high-strength porters connected together by means of a special AISI 304 stainless steel pin.

- Side rails, discharge hopper and collection apron in 15/10 shaped sheet of AISI 304 stainless steel.

Bucket elevator

Green tomato separator

Positioned inside the underground channel, it allows you removing a large part of the green tomato that floats on the surface of the water and conveying it outside, inside a bin.

Plants weeding machine

Positioned inside the duct, it allows you removing plants and/or tomato branches and conveying them outside to a bin.

- Entirely manufactured in AISI 304 stainless steel.

- Complete with stainless steel comb conveyor belt.

- Electrical panel for timed system control.

Tomato reception channel

This channel allows you to continuously receive the tomato that is unloaded in bulk together with the water from trucks or bins.

During unloading, foreign bodies deriving from mechanical collection such as stones and soil also enter the duct; this transforms into mud in contact with water, settles on the bottom of the duct, while clods of earth, small fragments, but above all stones of various sizes, settle on the mobile surface.

This system known as “Redler“, designed and manufactured in 1998, is composed of a mobile single-conveyor belt, entirely in stainless steel, which, positioned on the bottom of the duct, allows the rapid and continuous removal of foreign bodies outside.

Scraper elements are applied on the mobile single conveyor belt, which in the return translation allow the removal of the mud from the bottom of the duct and its removal by means of a timed valve.

A continuous water jet separator prevents the accidental rise of any entrainments of tomatoes on the inclined mobile surface of the Redler. The tomato unloaded together with the water on the opposite side of the Redler advances thanks to the flow and grumbling created by special electric blowers.

Nothing found.