Linear Dicers

Sa.178 Linear Dicer

True, unique and original.

More than 500 dicers installed worldwide.

- Perfect and regular cut

- Separating juice and seeds from tomato slices before dicing

- Ejector roller motorization system detectable in phase with the grid sectors (patented)

- Easy format change

- Removal of any pieces of peel from the dice

Supply capacity of approx. 12 t/h.

Available formats:

- 10x10mm

- 12x12mm

- 14x14mm

- 17x17mm

- 20x20mm

CuboRosso

Linear dicer machine for high production capacity and excellent quality.

Thanks to the new patented and innovative cutting system, the dicer machine can reach a supply capacity of approx. 18 t/h of peeled tomato.

Available formats:

- 12x12mm

- 14x14mm

- 17x17mm

- 20x20mm

Advantages

- Perfect and regular cut

- Separating juice and seeds from tomato slices before dicing

- Ejector roller motorization system detectable in phase with the grid sectors (patented)

- Easy format change

- Removal of any pieces of peel from the dice

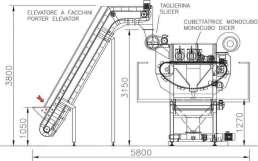

MonoCubo

Linear dicer machine for small production capacities and excellent quality.

Thanks to the new patented and innovative cutting system, the dicer machine can reach a supply capacity of approx. 6 t/h of peeled tomato.

Available formats:

- 10x10mm

- 12x12mm

- 14x14mm

- 17x17mm

- 20x20mm

Advantages

- Perfect and regular cut

- Separating juice and seeds from tomato slices before dicing

- Ejector roller motorization system detectable in phase with the grid sectors (patented)

- Easy format change

- Removal of any pieces of peel from the dice

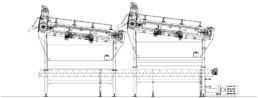

Roller Drainer

To remove a considerable part of the peel and eliminate the sagging tomatoes after the vacuum scalding treatment.

C700

Inspection Belt

For the visual inspection of the peeled or diced tomato before packaging.

- Stainless steel conveyor belt

- FDA modular conveyor belt

- Thermodrive conveyor belt

Distribution Belt

To receive the peeled tomato and convey it directly to the inspection or to the dicing lines. The distribution takes place through special electro-pneumatic bulkheads applied on the chutes.

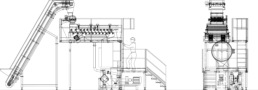

Peel Remover

For the removal of small pieces of peel

left after the peeling treatment.

It is the Finisher.

Depending on the production capacity, the Pinch Beds for Peel Removal can be used individually or in series.

The tomato coming from the peeler is conveyed onto the roller conveyor belt, which by rotating on themselves pinches the peel and remove it in the tank below.

Features:

- Constructive easiness

- Quick and timed washing system

- FDA certification and DIRECTIVE 2011/65/EU, with SUITABILITY FOR THE PROCESSING OF ORGANIC TOMATO

- Centralized lubrication system

- Total recovery of waste

Variety of models:

- Sa 307.570

- Sa 307.740

- C 107.601.2000/3000

- C 107.740.2000/3000

LunaPiena

Rotary (patented) Dicer

Production capacity of approx. 12 t/h of peeled tomatoes.

Simplicity of construction and easy change of format, which can be carried out by replacing the rotating basket

Basket sizes: 12mm, 14mm, 17mm.

Mechanical Peeler Sa206

Very high quality, all the maximum of the tomato!

Mechanical Tomato Peeler500 installed all over the world...

Universally the most chosen among the Peelers!

- Respect for tomatoes with blanching in hot water

- Surface incision of the peel

- Preservation of all the organoleptic properties of the tomato

- Very High Quality and Reliability

- Total recovery of waste

- Energy saving

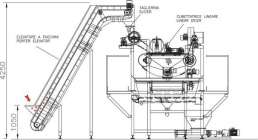

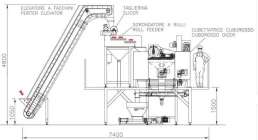

the mechanical peeling group consists of:

- Sa 103 scalding machine, models 500/700/900

- Porter elevator

- Mechanical Peeler Sa206, 2 channels/4 channels/6 channels models

- Pinch Bed for Peel Removal

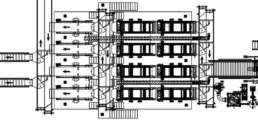

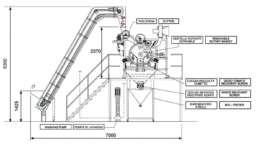

Saturno Peeler

TOMATO PEELING GROUPprovided with steam scalding, superheated water and vacuum cooling

- Great peeling efficiency with surface scalding

- Excellent quality

- High capacity

- Flexibility and reliability

- Energy saving

- Low maintenance costs

- High production capacity: 50÷55 t/h

ONLY THREE STEPSinside the peeler allow the tomato coming out with detached skin with no mistreatment.

Gianisa Pulper

Designed to obtain fresh, seared and/or peeled tomatoes,

small pieces between 6 and 12 mm in diameter,

thus limiting as much as possible the quantity of seeds and juice in the final product.

The product obtained by extrusion is commonly called “fine pulp“.

Production capacity: Up to about 10 t/h of peeled tomato supplied to the cutter.

Yield: About 40% of pulp, depending on the type of diet (seared or peeled tomato),

the degree of ripeness and the variety of the tomato.

Il gruppo di Polpa Fine a si compone di:

- Elevatore a Facchini

- Taglierina

- Piano vibrante

- Polpatrice Gianisa

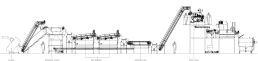

Roller sorting table

Made to allow manual sorting of fresh tomatoes on both sides of the plan. Conveyor belt composed of stainless-steel rollers, equipped with nylon terminals and applied on a special chain. Complete with lateral platforms to allow easy access of personnel to the sorting plan. Support structures in stainless steel section, complete with plates and counterplates to facilitate assembly. To convey the waste, it is possible to install side pockets or a central waste belt above the sorting table.